Arc welding is a welding method that uses the heat generated by arc discharge to melt the electrode and the workpiece and then cool and solidify to form a weld. In the welding process, an arc is created between two electrodes (usually the electrode and the workpiece), and the high temperature of the arc melts the metal at the contact site, thus forming a weld.

There are many types of arc welding, manual electrode arc welding, gas shielded arc welding, gas tungsten arc welding, submerged arc welding, argon arc welding.

Flash welding is a processing technology and connection method by heating, pressurizing, or both, with or without filling materials, to produce atomic bonding between two workpieces.

Flash welding has a wide range of applications, which can be used for both metals and non-metals. For example, low carbon steel, high carbon steel, alloy steel, stainless steel, aluminum, copper, titanium and other non-ferrous metals and alloys, can use flash welding. In addition, flash welding can also be used for dissimilar alloys, as well as a variety of plate, pipe, profiles, solid parts, tools and other welding.

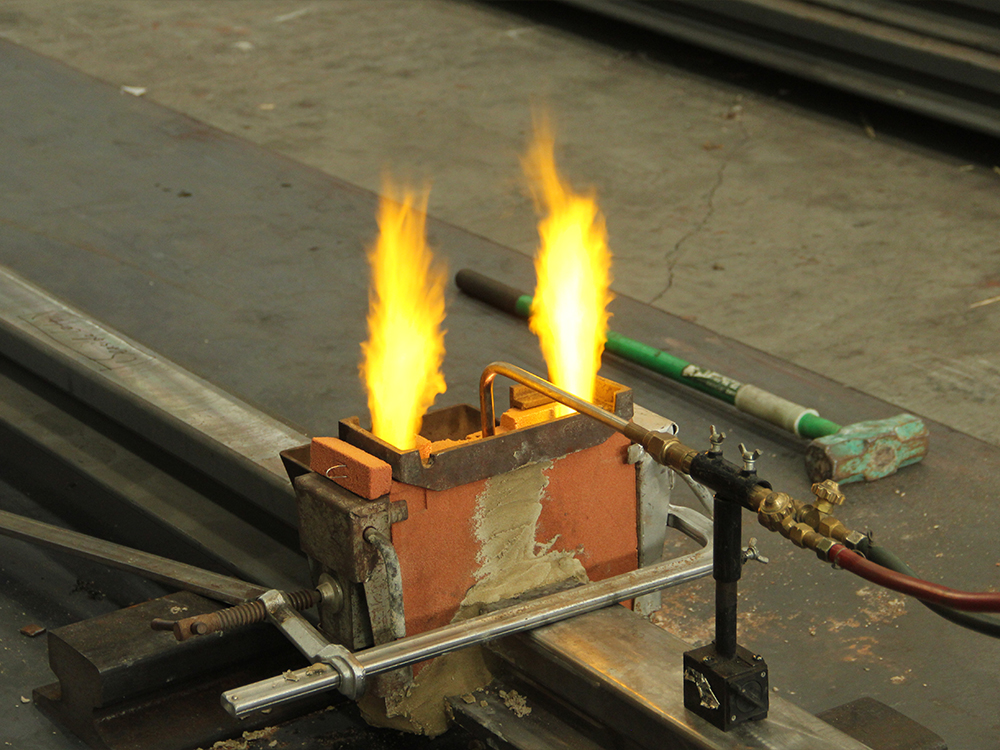

Thermit welding is the use of metal oxides (such as iron oxide, copper oxide, etc.) and the exothermic reaction between metal aluminum to produce high temperature molten metal, and then achieve welding method. This reaction can release a large amount of heat energy, the temperature of up to 3000 ° C, enough to melt and fuse the metal parts to be welded together.