High-Quality Crane Runway Design for Steel Mills | Leading Suppliers & Manufacturers

At SINCHOLD Co., Ltd., we specialize in designing crane runways specifically for steel mills, catering to the distinct requirements of your operations. Our custom solutions prioritize safety and efficiency, ensuring that our designs are not only robust enough to bear heavy loads but also durable for long-term usage in challenging environments. We work collaboratively with you to tailor our designs to your operational needs. Whether your facility includes towering structures or expansive factory floors, our runway designs are engineered to maximize crane performance. By choosing us, you're opting for reliability, expert craftsmanship, and a dedicated approach to creating runway solutions that empower your business operations. Elevate your efficiency with our expertly crafted designs tailored for your specific needs.Tips & Tricks for Steel Mills Crane Runway Design From Concept to Delivery Service Backed by Expertise

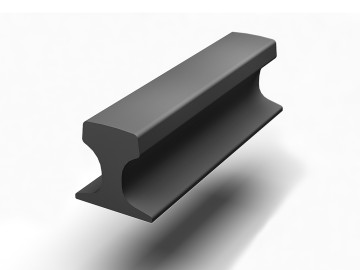

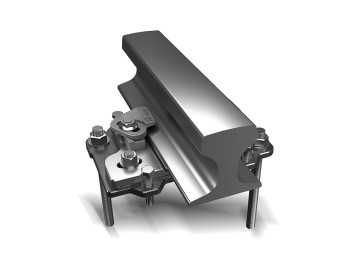

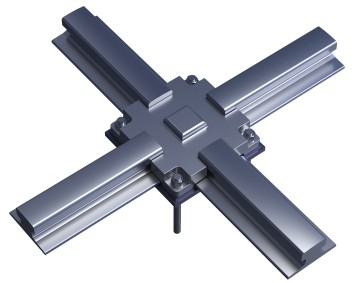

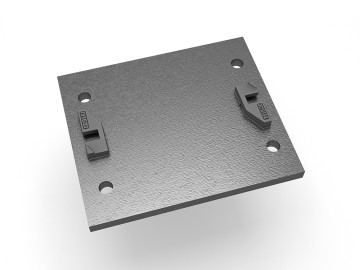

Designing an effective crane runway for steel mills is a crucial aspect of ensuring operational efficiency and safety. When embarking on this journey from concept to delivery, several tips and tricks can help streamline the process. First, consider the weight and type of loads the crane will handle. The runway design must accommodate the specific requirements of the steel mill environment, including factors like vibration, wear and tear, and potential thermal expansion. Collaborating with experienced engineers early in the design phase can help identify the best materials and structural configurations to support robust crane operations.

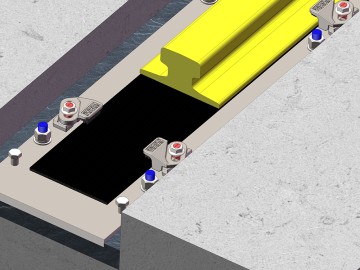

Additionally, the integration of high-quality rail fasteners and accessories is essential for a successful runway. Utilizing advanced rail fastening systems ensures that the crane operates smoothly, minimizing maintenance costs and downtime. It's vital to select components that not only meet industry standards but also are suited for the unique challenges of a steel mill. Regular assessments and technical services throughout the lifespan of the runway can further enhance performance, ensuring that the design remains effective and adaptable to future needs. With the right expertise and adherence to best practices, the journey from concept to implementation can result in a highly functional and reliable crane runway system.

Tips & Tricks for Steel Mills Crane Runway Design From Concept to Delivery Service Backed by Expertise

| Dimension | Details | Best Practices | Considerations |

|---|---|---|---|

| Load Capacity | Determine required capacity based on load types and frequencies. | Include a safety margin above expected loads. | Consider future upgrades and heavier loads. |

| Material Selection | Use high-strength materials for beams and supports. | Inspect materials for compliance with industry standards. | Consider corrosion resistance based on environment. |

| Design Standard | Follow local and international engineering standards. | Incorporate redundancy in critical design areas. | Regularly update designs to comply with revisions of standards. |

| Installation | Expert installation reduces future maintenance issues. | Conduct site inspections before installation. | Implement strict safety protocols during installation. |

| Maintenance Planning | Schedule regular inspections and maintenance tasks. | Use checklists for consistency in maintenance. | Document all maintenance for future reference. |

Step-by-Step Guide To Steel Mills Crane Runway Design Where Innovation Meets 2025 Industry Leaders

L

Lisa Chen

The product quality exceeded my expectations. Plus, the after-sales service was prompt and helpful, which made my experience even better.

12

June

2025

C

Chloe Anderson

The quality of this product is outstanding! Customer service was prompt, knowledgeable, and very polite.

26

May

2025

A

Addison Edwards

This product is built to last. The after-sales team’s professionalism and support were commendable.

16

May

2025

L

Luna Reed

Absolutely fantastic quality! The after-sales service team was efficient and professional.

30

May

2025

S

Sophia Martinez

Remarkable quality! The support team provided prompt and professional assistance, which I truly appreciated.

02

June

2025

J

Jaxon Bell

Outstanding craftsmanship! The efficiency of the after-sales service was truly remarkable.

31

May

2025