Custom Rail Grouting Solutions from Reliable Suppliers and Factories

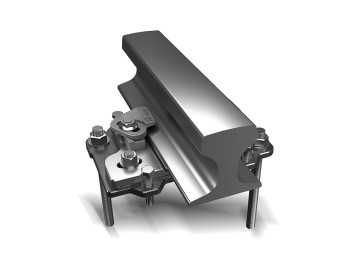

At SINCHOLD Co., Ltd., we specialize in premium Rail Grouting solutions tailored to meet your specific requirements. Our products are engineered for outstanding performance and long-lasting durability in rail systems, providing a solid foundation that enhances both safety and longevity. As a dedicated manufacturer, we offer competitive wholesale rates, enabling you to acquire the necessary quantities without compromising on quality. Whether supplying factories or serving discerning buyers, our extensive range guarantees the highest standards. Each Rail Grouting product undergoes rigorous testing to comply with industry benchmarks, ensuring exceptional value for your investment. Partner with us to strengthen the integrity of your railway infrastructure through our innovative solutions and benefit from the expertise of a trusted industry leader.7 Key Tips To Rail Grouting Trusted by Pros Service Backed by Expertise

When it comes to rail grouting, achieving a reliable and effective application is paramount for ensuring the longevity and safety of railway systems. At SINCHOLD, we understand the complexities of railway infrastructure and have curated essential tips trusted by professionals in the field. Here are seven key insights that can optimize your rail grouting process and enhance system performance.

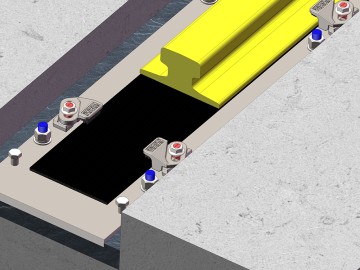

First, ensure that surface preparation is meticulous. Properly cleaning and preparing the area where grouting will take place minimizes the risk of contamination and promotes better adhesion. Second, selecting the right material is crucial; opt for high-quality grout that meets the specific requirements of your project. The viscosity, setting time, and mechanical properties should align with the environmental conditions and load expectations.

Moreover, execution is vital. Implementing systematic mixing and applying techniques—while ensuring accurate monitoring of ambient conditions—can significantly influence the overall effectiveness of the grouting process. At SINCHOLD, our expertise extends beyond just product provision. Our comprehensive range of rail fasteners and accessories, including our railway e-clip and turnout series, alongside our technical support services, equip project managers and contractors with the resources needed for successful implementation. Trust in our expertise to support your rail projects, ensuring a solid foundation for the future of your railway infrastructure.

7 Key Tips To Rail Grouting Trusted by Pros Service Backed by Expertise

| Tip | Description | Benefits | Expert Recommendation |

|---|---|---|---|

| 1. Choose the Right Grout | Select a grout type based on environmental conditions and application needs. | Ensures long-lasting stability and resistance to moisture. | Consult with manufacturers for the best product option. |

| 2. Correct Preparation | Prepare the surface by cleaning and removing debris before application. | Promotes better adhesion and reduces failure rates. | Use pressurized air and cleaning solvents as needed. |

| 3. Accurate Mixing | Mix grout according to manufacturer specifications for optimal performance. | Enhances flowability and setting time control. | Use a mechanical mixer for consistency. |

| 4. Proper Installation | Apply grout in an even manner, ensuring complete filling of voids. | Avoids air pockets and enhances structural integrity. | Utilize vibration for proper compaction. |

| 5. Monitor Temperature | Ensure grouting is done within the temperature range recommended. | Prevents premature curing or prolongation of setting times. | Use temperature gauges to keep track. |

| 6. Curing Process | Follow appropriate curing methods to achieve optimal strength. | Enhances final hardness and performance longevity. | Consider using curing compounds for efficient hydration. |

| 7. Regular Inspections | Conduct periodic checks to ensure grout health and integrity. | Identifies issues early and maintains safety standards. | Schedule annual inspections for best results. |

Why Invest In Rail Grouting Your Trusted OEM Partner Supplies the World’s Top Brands

M

Michael Johnson

These items are top-notch! The professionalism of the customer service team made a significant difference in my buying experience.

04

June

2025

J

Joshua Thomas

Very high-quality product. The after-sales team went above and beyond to ensure my satisfaction!

23

June

2025

A

Addison Edwards

This product is built to last. The after-sales team’s professionalism and support were commendable.

16

May

2025

J

Jaxon Bell

Outstanding craftsmanship! The efficiency of the after-sales service was truly remarkable.

31

May

2025

S

Sophia Bennett

Exceptional service! The support team was knowledgeable and resolved my queries in no time.

05

July

2025

S

Scarlett King

Incredible quality! You can tell this company takes pride in what they produce.

08

June

2025