One-Shot Crucible Suppliers & Manufacturers: Quality Solutions for Every Need

The One-Shot Crucible stands out for its exceptional durability and precision, making it ideal for various applications. Crafted from high-quality materials, this crucible ensures reliable performance even under harsh conditions. SINCHOLD Co., Ltd. is renowned for its meticulous craftsmanship and commitment to excellence, providing a product that meets the high standards required by businesses. With a focus on quality assurance, each One-Shot Crucible is designed for long-lasting efficiency, enhancing productivity in any operational setting. Trust in SINCHOLD's expertise to find the right solution for your needs.Key Methods For One-Shot Crucible Factory Trusted by Pros

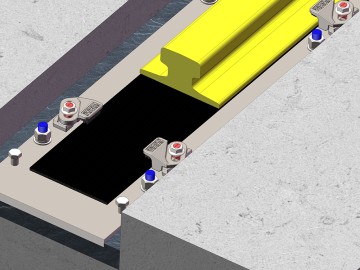

In the world of railway infrastructure, choosing the right supplier can significantly impact project success and safety. SINCHOLD stands out as an integrated manufacturer, renowned for its expertise in engineering, production, installation, and technical services related to rail fasteners and accessories. Our commitment to quality and innovation has made us a preferred choice for professionals seeking reliable solutions.

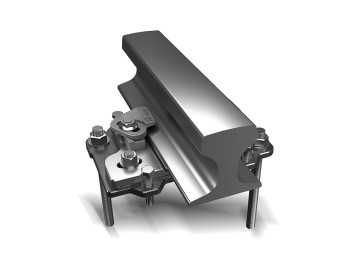

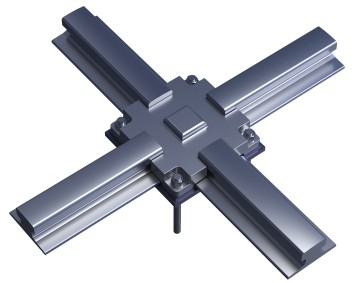

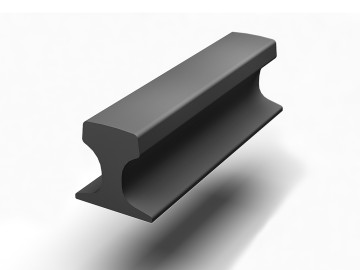

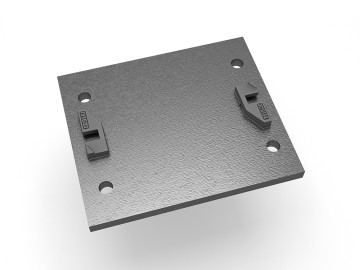

At SINCHOLD, we specialize in an array of products designed to enhance the durability and efficiency of railway systems, including our railway e-clip series, railway turnout series, and a comprehensive fastening system for railway tracks. Each product undergoes rigorous testing and quality assurance processes to ensure it meets industry standards and customer expectations. Our experienced team is dedicated to providing tailored solutions that address specific challenges faced by project managers and procurement professionals across the globe.

What sets SINCHOLD apart is not just our extensive product range but also our dedication to customer service. We understand the demands of international procurement and work closely with our clients to deliver prompt and efficient service, ensuring that all technical requirements are met. For global buyers looking for a trustworthy partner in railway fasteners, SINCHOLD promises not only exceptional products but also an unwavering commitment to quality and reliability, making us the go-to crucible factory for professionals worldwide.

Key Methods For One-Shot Crucible Factory Trusted by Pros

| Method | Description | Benefits | Challenges |

|---|---|---|---|

| Precision Heating | Utilizes advanced heating technology to ensure uniform temperature. | Improves product quality and reduces defects. | Requires careful calibration and maintenance. |

| Automated Process Control | Employs automated systems to monitor and adjust the manufacturing process. | Increases efficiency and consistency in production. | High initial setup costs and technical complexity. |

| Quality Control Testing | Incorporates rigorous testing methods to ensure product standards. | Identifies defects early and ensures compliance with industry standards. | Can slow production if not managed efficiently. |

| Material Selection | Focus on choosing high-quality, durable materials for production. | Enhances the final product's longevity and performance. | May increase overall costs if not carefully managed. |

| Rapid Prototyping | Utilizes 3D printing and other technologies to create prototypes quickly. | Speeds up the design process and encourages innovation. | Limited by material compatibility and production scale. |

Must-Know Tips For One-Shot Crucible Custom Solutions, Leads the Global Market

S

Sophia Williams

An exemplary product with excellent build quality. I appreciated the attentive after-sales service provided.

20

June

2025

J

Joshua Thomas

Very high-quality product. The after-sales team went above and beyond to ensure my satisfaction!

23

June

2025

E

Ella Rodriguez

Incredible quality! The after-sales team was extremely helpful and knowledgeable.

19

June

2025

O

Olivia Martin

High-quality product with an impressive performance. I’m extremely pleased with my purchase!

05

June

2025

E

Ethan Johnson

The response time from customer support was fantastic. They really know their products well.

09

May

2025

M

Matthew Wright

I’m very pleased with my purchase! The after-sales service was prompt and very professional, a rare find these days.

16

June

2025