Gantrex Weldable Rail Clips: Custom Solutions from Leading Manufacturer & Supplier

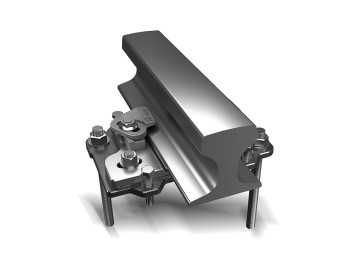

Our Gantrex Weldable Rail Clips are an essential choice for anyone in need of reliable rail solutions. Crafted for durability and performance, these clips are designed to meet the exacting standards of any rail application. As a specialized manufacturer of rail accessories, we prioritize delivering high-quality products that cater to your unique requirements. With a focus on precision engineering, our clips contribute to the safety and efficiency of your rail systems. In the competitive B2B landscape, we understand the necessity of affordable pricing and prompt delivery, ensuring you receive exceptional support throughout your purchasing process. Partner with us for rail solutions tailored to your business needs.

Methods To Gantrex Weldable Rail Clips Stands Out Service

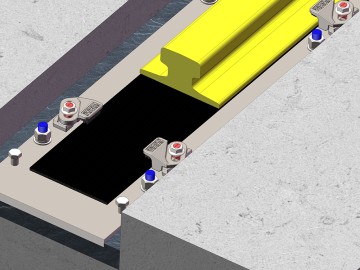

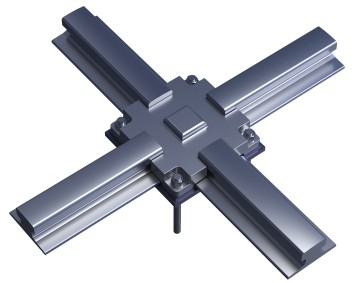

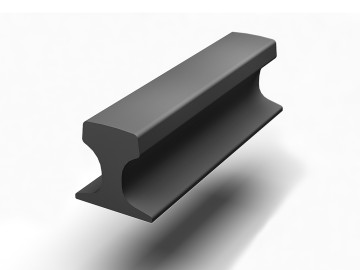

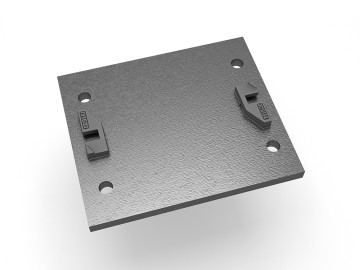

When it comes to rail infrastructure, the efficiency and safety of rail systems heavily depend on the quality of rail fasteners and accessories. One method to ensure superior performance in this area is the use of Gantrex weldable rail clips. These clips are engineered for durability and stability, providing an essential solution for securing tracks effectively. The unique design of weldable rail clips allows them to be permanently fixed to the rail, enhancing the overall integrity of the track while minimizing maintenance needs.

An outstanding service aspect associated with Gantrex weldable rail clips is their adaptability to various railway systems. Whether it’s a high-speed rail network or a heavy-load freight line, these clips meet the specific demands of each application, ensuring that they can withstand environmental factors and operational stresses. Additionally, technical support and installation services provided by experienced professionals further enhance the user experience, ensuring that the products perform flawlessly in the field.

In a competitive global market, it is crucial for procurement specialists to choose suppliers that not only provide high-quality products but also stand out for their commitment to service excellence. The integration of production, installation, and technical support facilitates seamless operations, making Gantrex weldable rail clips a valuable asset for any railway project. By investing in these advanced fastening solutions, businesses can significantly improve their track performance, leading to safer and more efficient rail transport.

Methods To Gantrex Weldable Rail Clips Stands Out Service

| Method | Description | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| TIG Welding | Uses a non-consumable tungsten electrode. | High precision and clean welds. | Slower process compared to others. | Used in delicate applications requiring precision. |

| MIG Welding | Uses a continuous wire feed as an electrode. | Faster welding speeds and great for thick materials. | Less control over weld quality. | Commonly used in heavy fabrication. |

| Stick Welding | Involves the use of a consumable electrode coated in flux. | Good for outdoor applications and rusty metal. | Less suitable for thin materials. | Used in construction and repair work. |

| Flux-Cored Arc Welding (FCAW) | Uses a tubular wire filled with flux. | Versatile for different positions and metals. | Can produce more smoke and spatter. | Ideal for construction and shipbuilding. |

| Laser Welding | Utilizes a laser beam to melt the material. | High-speed and deep penetration. | High equipment cost and complexity. | Used in automotive and aerospace industries. |

The Secret to Gantrex Weldable Rail Clips Ahead of the Curve Stands Out

J

James Thompson

I am truly impressed with the quality of these goods. The attention to detail is evident, and the support team was exceptionally knowledgeable.

20

June

2025

W

Wyatt Campbell

A truly exceptional product! The expertise and professionalism of the after-sales staff stood out.

13

June

2025

M

Mia Taylor

This product is truly exceptional. The quality speaks for itself, and I love using it every day.

14

May

2025

L

Layla Allen

This product is definitely worth the investment. Quality like this is hard to find.

08

May

2025

J

James Carter

Amazing customer support! They were attentive and really helped me with my concerns.

22

May

2025

M

Michael Smith

I appreciate the excellent build quality. The after-sales service was outstanding; the representative was knowledgeable and resolved my issue swiftly.

06

June

2025