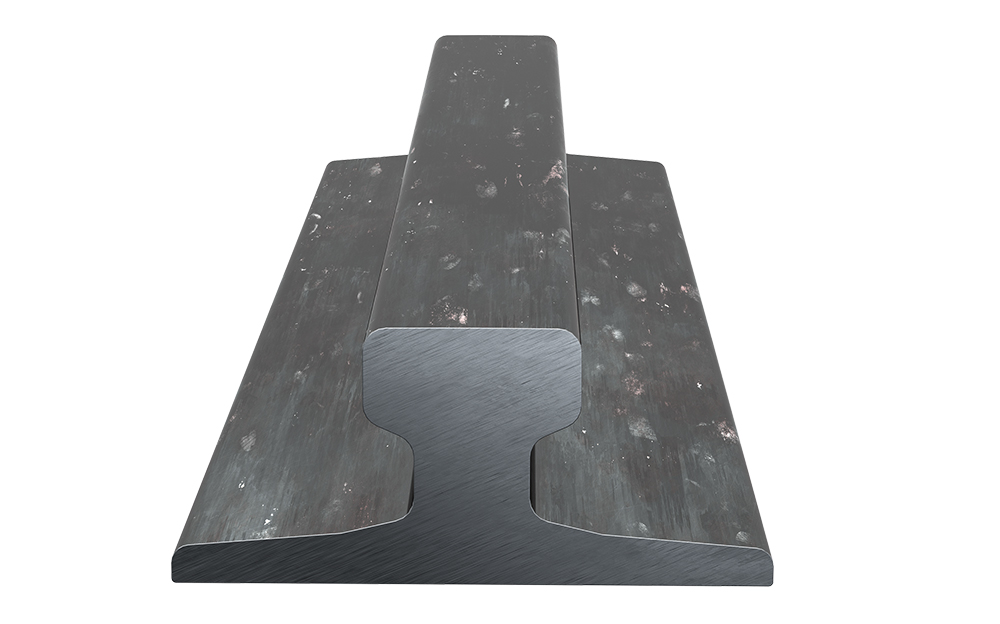

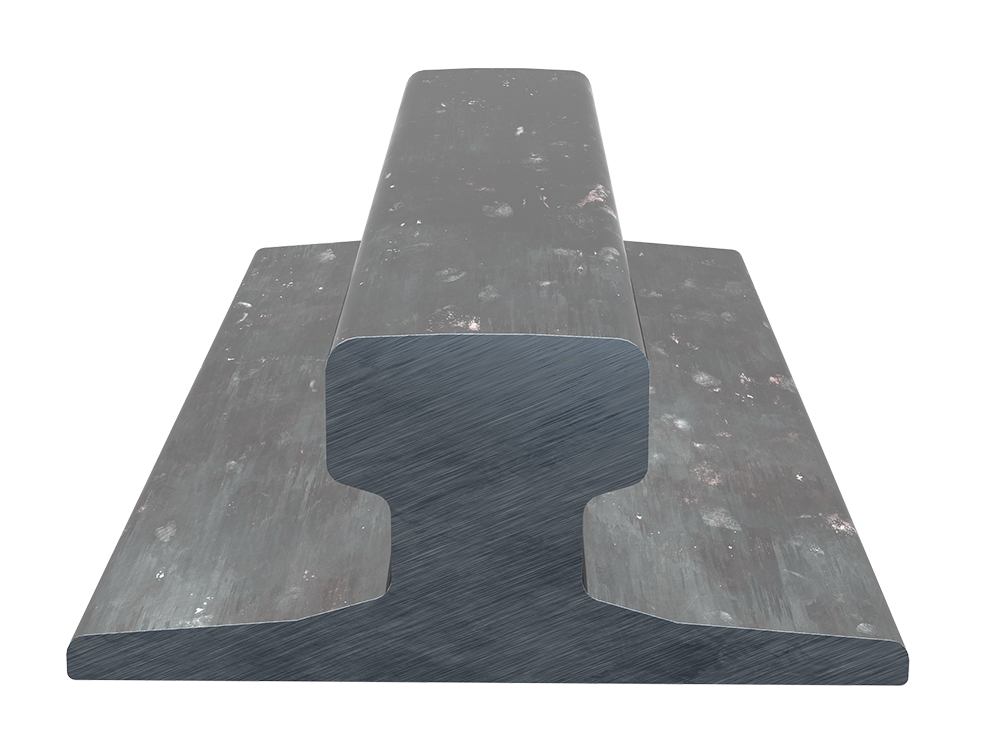

The DIN 536-1 Crane Rail A45 is a standardized rail profile designed for use in overhead cranes, gantry cranes, and other heavy-duty material handling systems. It is part of the DIN 536-1 series, which specifies dimensions, tolerances, and technical requirements for crane rails.

Key Specifications:

● Profile Designation: A45 (22.1 kg/m).

● Material: Typically made from high-quality steel (e.g., R260/R350HT/50Mn grade…) for excellent wear resistance and load-bearing capacity.

● Head Width (45mm): Designed with a broad head to distribute load and reduce wear on wheels.

● Foot Width (125mm): Ensures stable fastening to the supporting structure.

● Height (55mm) & Web thk (24mm) : Optimized for strength and compatibility with standard crane wheels.

● Length: Commonly supplied in 6m, 12m, or custom lengths.

Applications:

● Industrial Cranes: Used in workshops, warehouses, and steel plants for overhead traveling cranes.

● Ports and Shipyards: Suitable for gantry cranes handling heavy containers or bulk materials.

● Mining and Logistics: Deployed in heavy-duty environments requiring robust rail support.

● Railway Maintenance: Occasionally used in specialized railway crane systems.

Advantages:

● High durability under dynamic loads.

● Precise dimensional compliance with DIN standards for interchangeability.

● Compatible with standard rail clips, bolts, and fishplates for secure installation.

The DIN 536-1 A45 crane rail ensures reliable performance in demanding applications, combining strength, precision, and longevity.

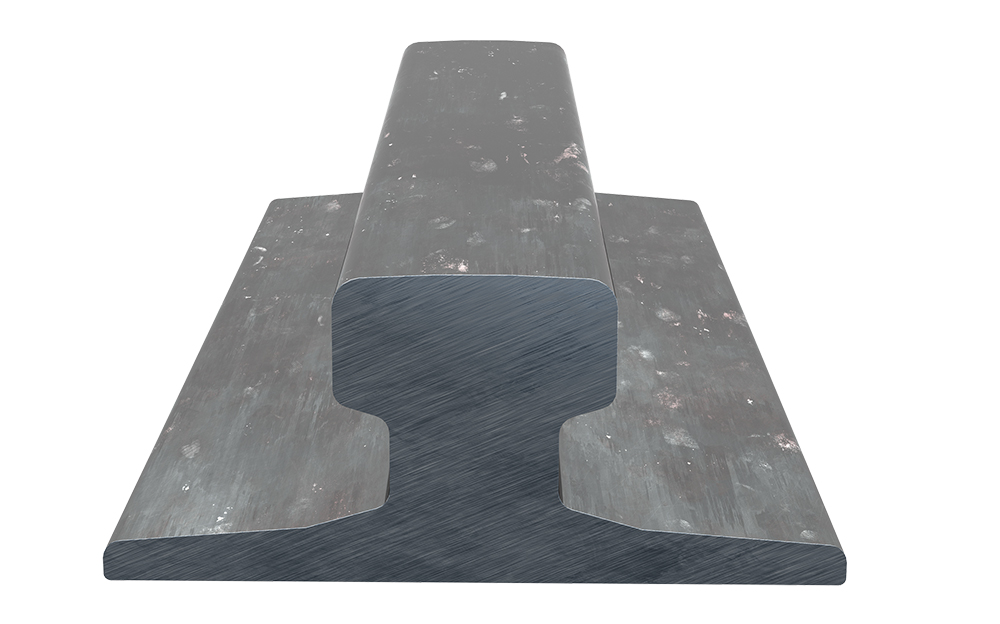

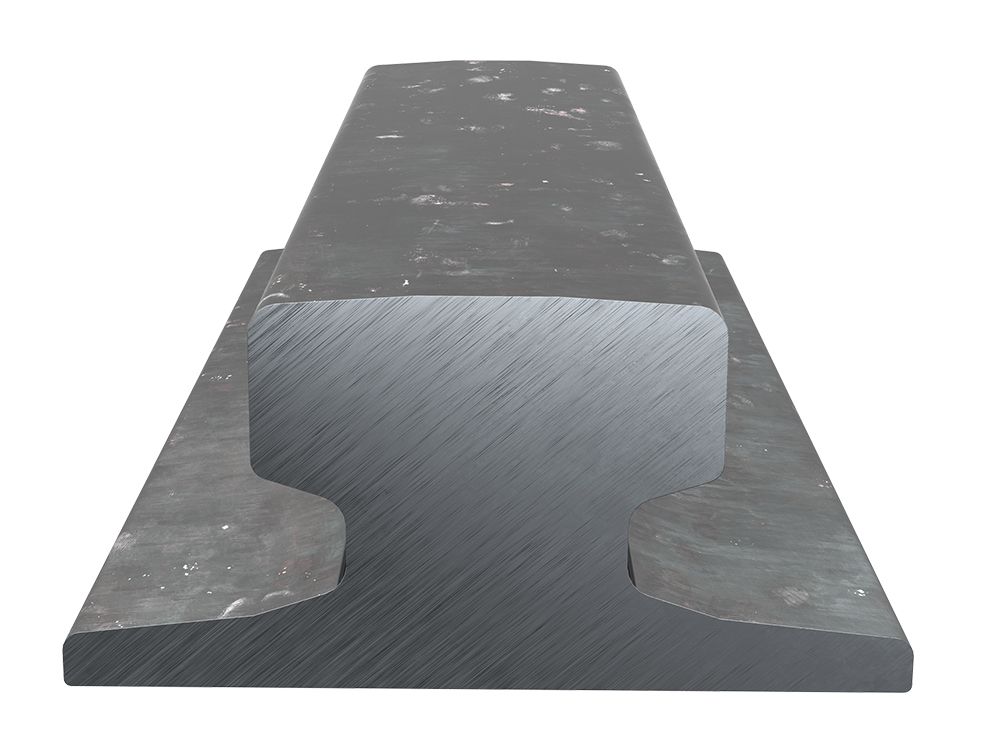

The DIN 536-1 Crane Rail A55 is a heavy-duty rail profile designed for demanding crane and material handling applications. As part of the DIN 536-1 standard, it ensures precise dimensions, high load-bearing capacity, and long service life under extreme conditions. This rail is commonly used in industrial, port, and heavy-lifting environments where reliability and durability are critical.

Key Specifications:

● Profile Designation: A55 (31.8 kg/m).

● Material: High-strength steel (typically R260, R350HT, 50Mn or similar grades) for superior wear resistance and fatigue strength.

● Head Width (55mm): Optimized for even load distribution, reducing wear on crane wheels.

● Foot Width (150mm): Provides stable mounting on concrete, steel, or wooden sleepers.

● Height (65) & Web Thickness (31mm): Engineered for maximum rigidity and impact resistance.

● Standard Lengths: Usually supplied in 6m, 12m, or custom lengths as per project requirements.

● Surface Hardness: Often heat-treated for enhanced durability in high-stress applications.

Typical Applications:

● Steel Mills & Foundries: Supports heavy-duty overhead cranes handling molten metal, coils, and large machinery.

● Ports & Container Terminals: Used in gantry cranes, STS cranes, and RTGs for lifting shipping containers.

● Mining & Heavy Industry: Suitable for ore bridges, stacker-reclaimers, and large-scale material handling systems.

● Railway & Logistics: Deployed in heavy-duty workshop cranes and transfer cars.

● Power Plants & Construction: Supports heavy lifting equipment in turbine halls and large construction projects.

Advantages:

✔ High Load Capacity – Designed for dynamic and static loads in harsh environments.

✔ Dimensional Precision – Complies with DIN 536-1 standards for compatibility with crane wheels and fastening systems.

✔ Long Service Life – Resistant to abrasion, deformation, and impact due to high-quality steel.

✔ Easy Installation – Compatible with standard rail clips, bolts, and fishplates for secure attachment.

Installation & Maintenance:

● Should be mounted on a properly aligned and reinforced base (steel structure or concrete sleepers).

● Regular lubrication and inspection of rail joints and wheel contact surfaces are recommended.

● Suitable for welded or bolted connections depending on operational requirements.

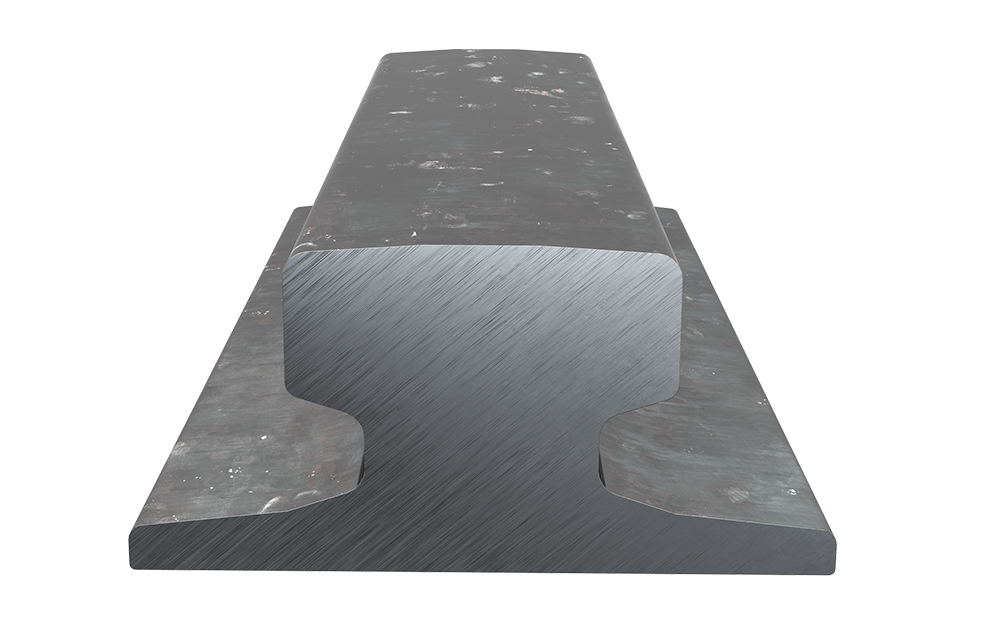

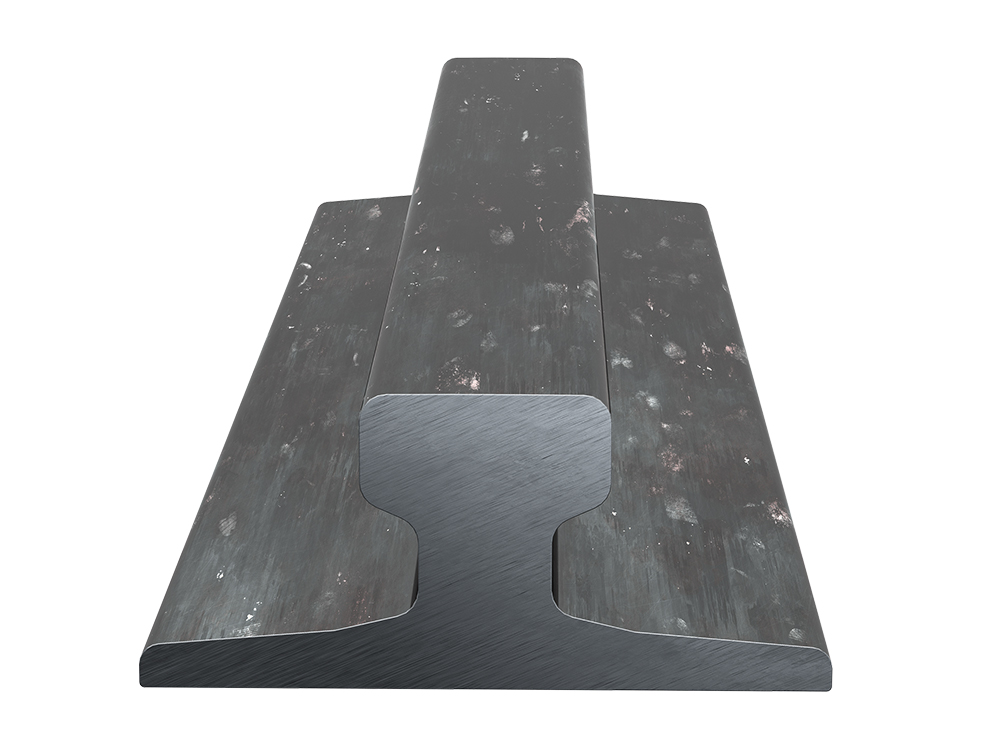

The DIN 536-1 Crane Rail A65 is a heavy-duty rail profile designed for extreme-load crane systems and industrial applications. As part of the DIN 536-1 standard, it ensures high strength, dimensional precision, and exceptional wear resistance, making it ideal for demanding environments such as ports, steel plants, and mining operations.

Key Specifications

● Profile Designation: A65 (43.1 kg/m).

● Material: High-grade steel (R260, R350HT, U71Mn or alloy steel of similar grades) with optional heat treatment for enhanced hardness.

● Dimensions:

Head width (65mm): Optimized for heavy wheel contact, reducing deformation.

Foot width (175mm): Ensures secure fastening to support structures.

Height (75mm) & web thk (38mm): Engineered for maximum load distribution and bending resistance.

● Standard Lengths: 6m, 12m, or customized (up to 25m for welded installations).

● Surface Hardness: Typically 200–300 HB (can be hardened to 320+ HB for abrasive environments).

Typical Applications

1. Heavy Industrial Cranes:

Steel mills: Ladle cranes, slab-handling cranes.

Foundries: Overhead cranes for molten metal transport.

2. Ports & Terminals:

Ship-to-shore cranes (STS), RTGs, and bulk material handlers for containers/ore.

3. Mining & Bulk Handling:

Ore bridges, stacker-reclaimers, and bucket-wheel excavators.

4. Power Plants & Heavy Construction:

Turbine hall cranes, heavy-lift gantry systems.

Advantages

✔ Ultra-High Load Capacity – Supports dynamic loads up to 1,000+ metric tons.

✔ Durability: Resistant to impact, abrasion, and plastic deformation even under cyclic stresses.

✔ Standard Compliance: Meets DIN 536-1 tolerances for seamless integration with crane wheels (e.g., DIN 15046).

✔ Installation Flexibility: Compatible with bolted joints, welded rails, or embedded systems.

Installation Notes

● Foundation Requirements: Requires rigid support (steel girders or reinforced concrete).

● Fastening: Uses clips, fishplates, or epoxy anchoring depending on substrate.

● Maintenance: Regular inspection for wheel-rail alignment, lubrication, and joint integrity.

Conclusion

The DIN 536-1 A65 is the go-to rail for ultra-heavy crane systems, combining robust engineering, standardized reliability, and long service life. Its design minimizes downtime in critical operations, making it a cost-effective solution for extreme-duty applications.

The DIN 536-1 Crane Rail A75 is a standardized crane rail profile commonly used in overhead crane systems and industrial rail applications. It conforms to the DIN 536-1 standard, which specifies dimensions, tolerances, and mechanical properties for crane rails used in heavy-duty material handling environments.

1. Profile Characteristics

● Designation: A75 (56.2kg/m)

● Material: High-carbon steel (typically R260 or R350HT grade)

● Surface Hardness: 200-300 HB (Brinell scale)

2. Mechanical Properties

● Tensile strength: ≥690 MPa

● Yield strength: ≥430 MPa

● Elongation: ≥10%

3. Typical Applications

● Heavy Industrial Cranes:

Steel plant ladle cranes

Foundry overhead cranes

● Port Equipment:

Container gantry cranes

Ship-to-shore cranes

● Special Applications:

Nuclear facility handling systems

Heavy machinery assembly lines

4. Key Features & Advantages

● Optimized head profile for superior wheel contact

● Standardized dimensions ensure interchangeability

● Robust construction for extreme dynamic loads

● Compatible with all standard rail fastening systems

● Corrosion-resistant options available

● Excellent load-carrying capacity

● Designed for high durability and wear resistance

● Suitable for both indoor and outdoor installations

● Complies with European standards for industrial crane systems

5. Installation Guidelines

● Foundation: Steel structure or reinforced concrete (grade ≥C35)

● Fastening: Clips, bolts or welding (with preheating)

● Maintenance: Regular lubrication and alignment checks recommended

6. Quality Assurance

● Manufactured under EN 10204 3.1 certification

● 100% dimensional inspection

● Full-length ultrasonic testing available

● Traceability from raw material to finished product

7. Reference Standards

● Primary: DIN 536-1:1985

● Material: EN 13674-1

● Testing: ISO 148 (Charpy impact test)

The DIN 536-1 Crane Rail A100 is a heavy-duty crane rail profile designed for use in demanding industrial environments. It complies with the DIN 536-1 standard, which defines the dimensional and mechanical requirements for crane rails used in overhead cranes, gantry systems, and other material handling applications.

This rail type offers excellent load-bearing capacity, wear resistance, and long service life, making it ideal for high-load and high-frequency operations.

1. Profile Characteristics

● Designation: A100 (74.3kg/m)

● Material: High-carbon steel (typically R260 or R350HT grade or U71Mn etc.)

● Surface Hardness: 200-300 HB (Brinell scale)

2. Typical Applications

● Heavy Industrial Cranes:

Steel plant ladle cranes (200+ ton capacity)

Foundry overhead cranes for molten metal handling.

● Port & Shipyard Equipment:

Container gantry cranes (STS, RTG)

Heavy-duty shipyard rail systems.

● Mining & Bulk Handling:

Ore bridge conveyors and stacker-reclaimers.

● Special Applications:

Nuclear power plant cranes (high load-bearing requirements).

3. Key Features & Advantages

✔ High Load Capacity – Designed for dynamic loads up to 1,000 metric tons.

✔ Optimized Head Profile – 100mm width ensures stable wheel contact and reduced wear

✔ Standardized Dimensions – Ensures compatibility with DIN-compliant fastening systems (clips, bolts, welding).

✔ Durability – Resistant to abrasion, impact, and plastic deformation under cyclic stresses, designed for long-term reliability under harsh operating conditions

✔ Suitable for both indoor and outdoor installations

✔ Compliant with European standards for industrial lifting and transport systems

4. Installation & Maintenance

● Foundation Requirements:

Steel support structures (DIN 18800) or reinforced concrete (≥C35).

● Fastening Methods:

Heavy-duty rail clips (KPO type) or welded joints (preheating required).

● Maintenance:

Regular ultrasonic testing (EN 13674-1).

Lubrication of wheel-rail contact surfaces.

5. Quality Assurance

● EN 10204 3.1 certification (material traceability)

● 100% dimensional inspection.

● Ultrasonic flaw detection (full-length testing).

supplied and installed by Sinchold for Maritime Yard, Saudi Aramco

The DIN 536-1 Crane Rail A120 is a standardized rail profile designed for overhead cranes, gantry cranes, and other heavy-duty material handling systems. It is part of the DIN 536-1 standard, which specifies dimensions, tolerances, and technical requirements for crane rails used in industrial and logistical applications.

Key Specifications:

● Profile Designation: A120 (100 kg/m).

● Material: Typically made of high-quality steel (e.g., R260/R350HT grade, U71Mn etc.) for excellent wear resistance and load-bearing capacity.

● Head Width: 120 mm (provides a broad running surface for crane wheels).

● Height: 105 mm (optimized for stability under dynamic loads).

● Base Width: 220 mm (ensures secure fastening to support structures).

● Standard Length: Usually supplied in 12 m or custom lengths.

Applications:

● Overhead Cranes: Used in workshops, warehouses, and production facilities.

● Gantry Cranes: Suitable for ports, shipyards, and outdoor heavy-load operations.

● Industrial Tracks: For transfer cars, bogies, and automated transport systems.

● Mining & Steel Mills: High durability under extreme loads and harsh environments.

Advantages:

● High Load Capacity: dynamic loads up to 1,000 metric tons with minimal deformation.

● Precision Engineering: Complies with DIN standards for dimensional accuracy.

● Long Service Life: Resistant to abrasion and mechanical stress.

The DIN 536-1 Crane Rail A150 is a heavy-duty rail profile designed for demanding crane and material handling applications. As part of the DIN 536-1 standard, it ensures high load capacity, durability, and precise dimensional tolerances for industrial use. This rail is commonly employed in environments requiring robust support for heavy loads, such as steel plants, ports, and large-scale logistics facilities.

Key Specifications:

● Profile Designation: A150 (150.3 kg/m).

● Material: High-strength steel (typically R260, R350HT, U71Mn or similar grades) for superior wear and impact resistance.

● Head Width: 150 mm (wide contact surface for smooth crane wheel movement).

● Height: 150 mm (enhanced vertical stability under heavy loads).

● Base Width: 220 mm (ensures secure fastening to foundation structures).

● Standard Length: Usually supplied in 12 m lengths, but custom lengths are available.

Applications:

● Heavy-Duty Overhead Cranes: Used in steel mills, foundries, and large manufacturing plants.

● Gantry & STS Container Cranes: Ideal for ports, shipyards, and heavy-load terminals.

● Industrial Rail Systems: Supports transfer cars, heavy-duty bogies, and automated transport systems.

● Mining & Heavy Machinery: Suitable for high-stress environments with extreme dynamic loads.

Advantages:

✔ Exceptional Load-Bearing Capacity – Designed for extreme weights (dynamic loads up to 1,600 MT) and long-term durability.

✔ Precision Manufacturing – Complies with DIN 536-1 standards for consistent quality.

✔ Wear & Corrosion Resistance – High-grade steel ensures longevity even in harsh conditions.

✔ Compatibility – Works with standard rail fasteners (clips, bolts, and sleepers) for secure installation.

supplied and installed by Sinchold for Maritime Yard, Saudi Aramco

DIN Crane Rail A45

DIN Crane Rail A55

DIN Crane Rail A65

DIN Crane Rail A75

DIN Crane Rail A100

DIN Crane Rail A120

DIN Crane Rail A150