Custom Electric Arc Welding Rail Solutions from Top Suppliers and Manufacturers

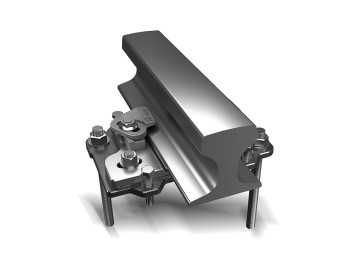

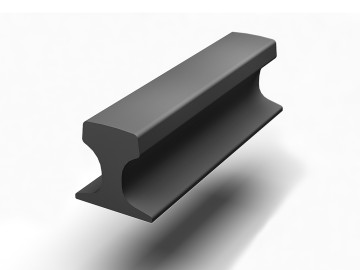

Electric Arc Welding Rails offer an essential solution for heavy industries that require dependable and high-performance welding equipment. SINCHOLD Co., Ltd. stands out as a manufacturer that deeply understands the challenges faced in the welding market, particularly among buyers navigating the competitive landscape in China. Their electric arc welding rails are engineered for exceptional performance and unmatched durability, making them suitable for a wide range of applications. With a focus on precision, these rails provide a cost-effective option without compromising on quality. SINCHOLD's commitment to excellent customer service and timely deliveries ensures a seamless purchasing experience. For those needing to enhance their welding operations and secure reliable partnerships, SINCHOLD's electric arc welding rails represent a strategic choice built on quality and trust.The Secret to Electric Arc Welding Rail Service Now Trending

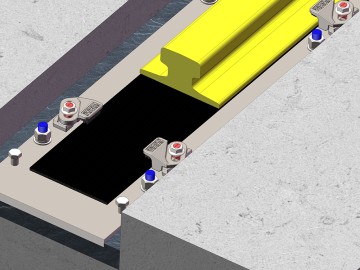

Electric arc welding is emerging as a revolutionary technique in the realm of rail service maintenance, capturing the attention of global procurement specialists seeking innovative solutions. This method offers unparalleled precision and efficiency, making it an ideal choice for key components such as rail fasteners and accessories. The growing trend of electric arc welding in rail service signifies a shift towards enhanced durability and reliability, essential factors for the safety and longevity of railway systems.

As industries push toward modernization, the advantages of electric arc welding are becoming increasingly clear. This technology allows for stronger bonds between materials, reducing the likelihood of failures and costly repairs. Moreover, the integration of electric arc welding in manufacturing processes streamlines operations, ensuring that products like railway e-clips, turnouts, and fastening systems are not only robust but also produced with greater speed and cost-effectiveness. Global procurement professionals must consider incorporating these advanced welding techniques to stay competitive in an evolving market.

In this context, the demand for suppliers who offer comprehensive solutions—encompassing production, installation, and technical services—has never been more crucial. By embracing electric arc welding, suppliers can enhance their service offerings, ensuring that clients receive the highest quality rail components. As the industry continues to trend toward this method, now is the time for procurement specialists to prioritize partnerships that leverage this innovative technology, setting the stage for a more efficient and sustainable railway infrastructure.

The Secret to Electric Arc Welding Rail Service Now Trending

| Service Type | Duration (Hours) | Expertise Level | Typical Cost ($) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Standard Rail Welding | 4 | Intermediate | 150 | 95 |

| Heavy-Duty Rail Welding | 6 | Advanced | 250 | 90 |

| Emergency Repair Welding | 2 | Expert | 300 | 98 |

| Routine Maintenance Welding | 3 | Intermediate | 100 | 92 |

Best Chinese Electric Arc Welding Rail Industry Giant For the Current Year

B

Benjamin Wright

The product’s build quality is impressive. It’s holding up beautifully after extensive use.

16

May

2025

C

Chloe Adams

This product delivers on all fronts! Excellent quality that meets my needs perfectly.

19

June

2025

A

Avery Murphy

The product is a game changer! Its quality makes my work so much easier.

14

June

2025

D

Daniel Reed

The support team displayed exemplary professionalism, making my buying experience smooth and easy.

27

June

2025

M

Michael Smith

I appreciate the excellent build quality. The after-sales service was outstanding; the representative was knowledgeable and resolved my issue swiftly.

06

June

2025

L

Laura Davis

The craftsmanship of this product is outstanding. The support I received was prompt and effective—a true testament to their commitment to service.

10

May

2025