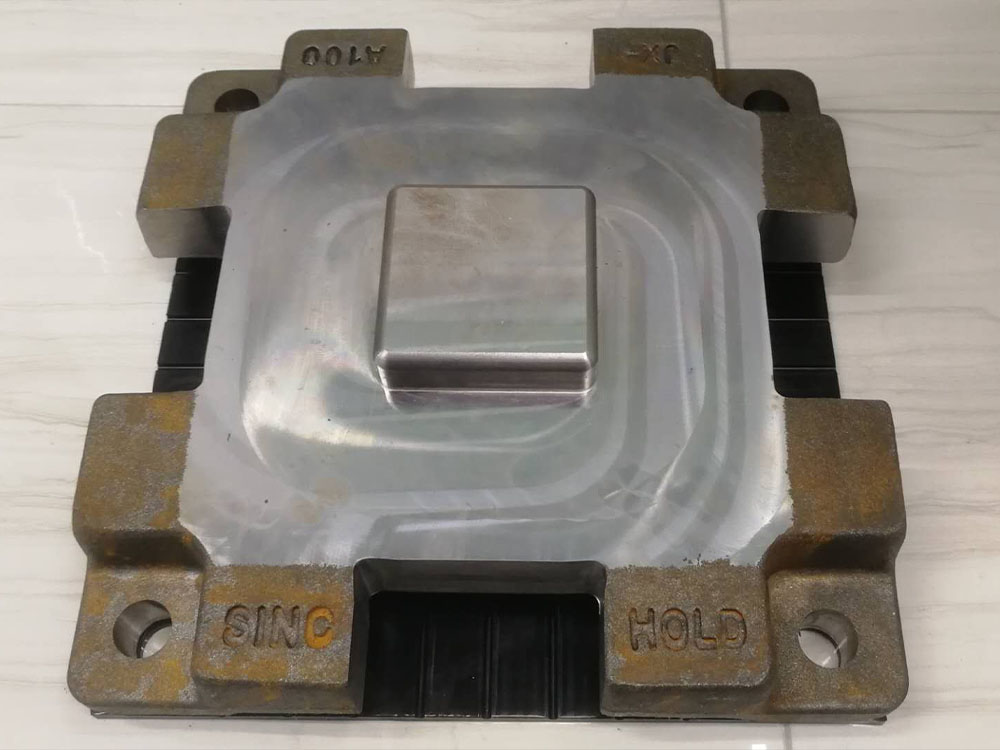

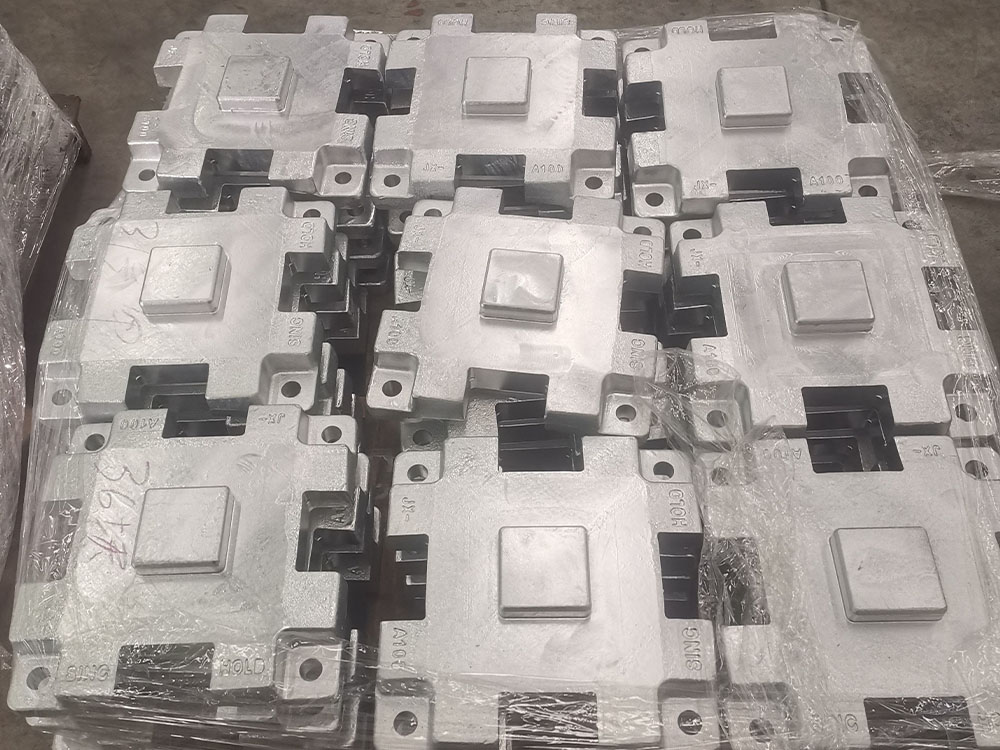

Forged from high-hardness, high-strength alloy steel (42CrMo) (casting is optional according to different applications), providing excellent mechanical properties (compression, tensile, and wear resistance). The Brinell hardness reaches 405-447HB, with UTS ranging from 1380 to 1520MPa, ensuring the product's robustness, durability and reliability. Surface Treatment: Hot-dip galvanized to enhance corrosion resistance, suitable for harsh industrial environments.

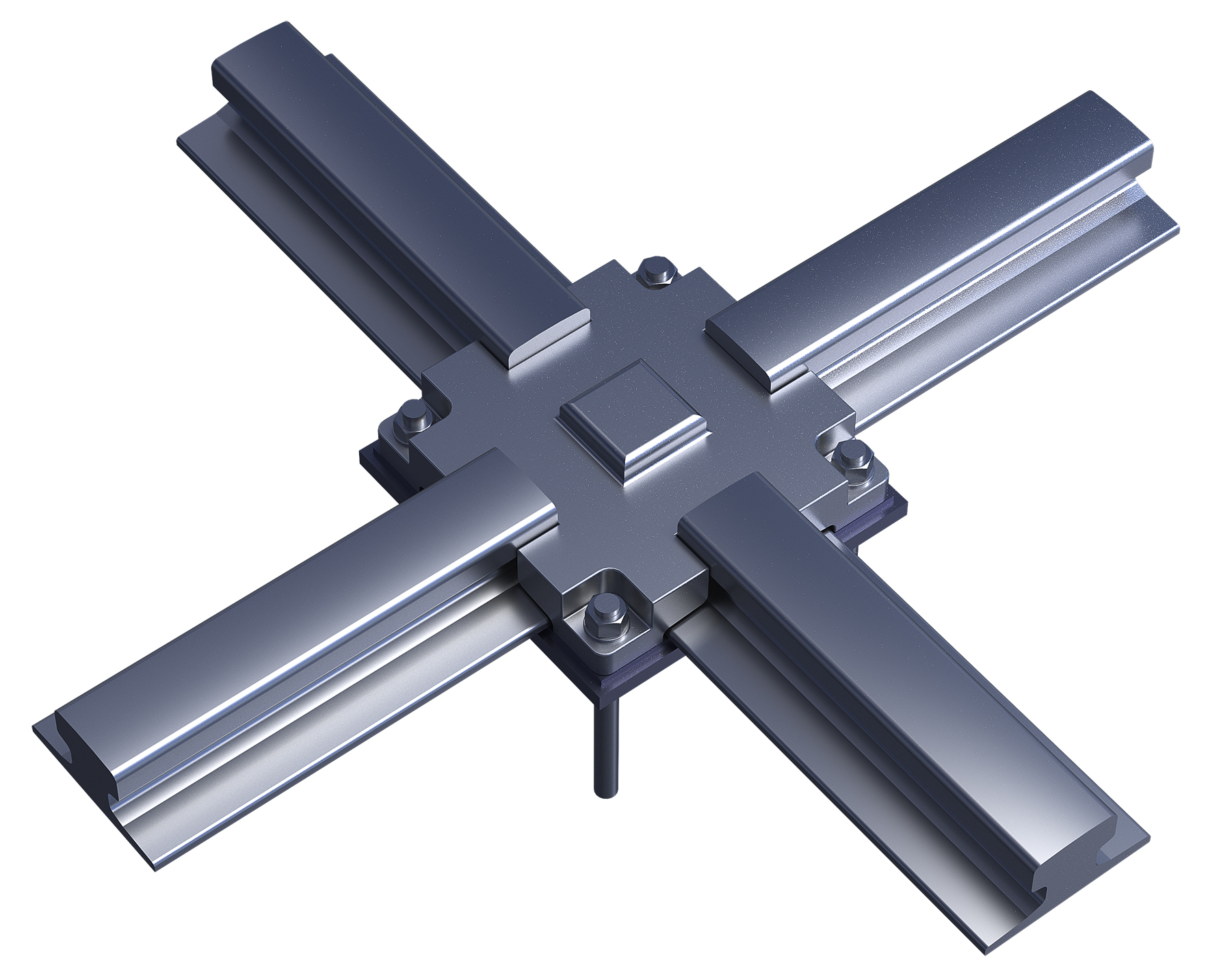

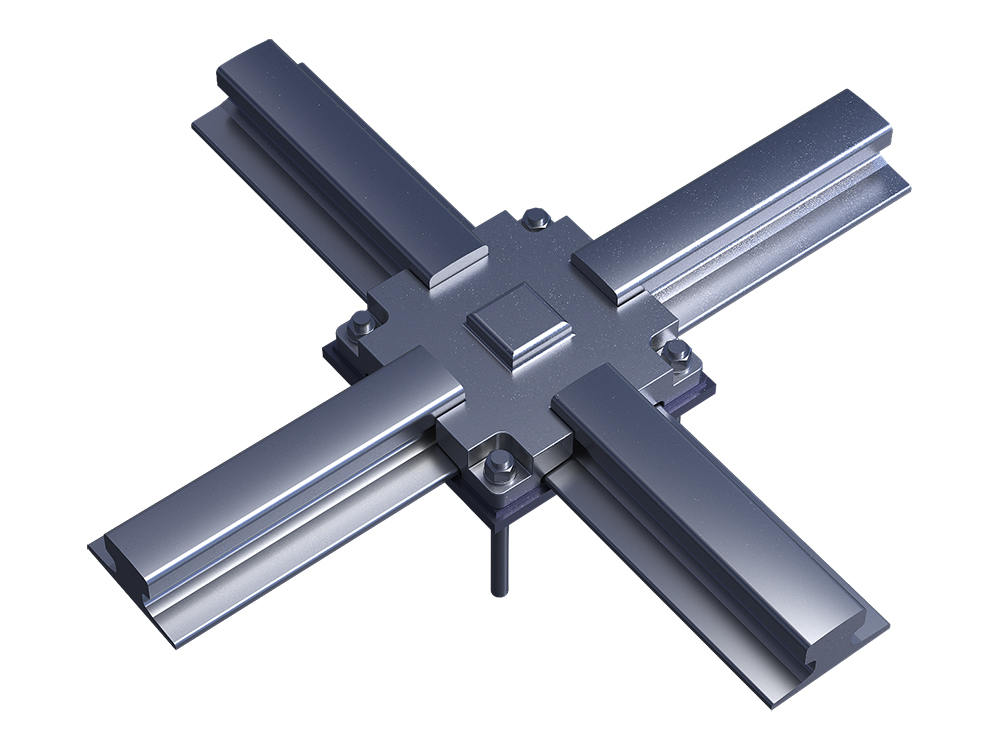

The crossover forging assembly is designed to tightly integrate the ends of rails from four directions into a single unit. It is securely fastened to the concrete ground using four high-strength anchor bolts, custom-made soleplates, and rubber pads, effectively preventing displacement caused by vibration or external forces.

This connection structure allows multiple pieces of equipment (such as cranes) on different lines within the same area to operate smoothly and seamlessly without interfering with each other, significantly enhancing the operational efficiency and safety of the lines. The Sinchold Crossover Forging/Casting Assembly is an essential component for maintaining the stability and safety of railway or crane track systems, especially in areas where multiple track lines intersect. Its robust design and superior performance characteristics make it an ideal choice for improving space utilization in demanding industrial applications.

Compatible Models: Customizable to meet customer needs, compatible with common crane rail models (e.g., QU70, QU80, QU100, QU120, A65, A100, A150, etc.).

● Industrial Crane Systems: Enables material handling equipment to operate on tracks in different directions within factories, ensuring smooth and efficient movement of heavy loads.

● Ports and Terminals: Facilitates direction switching for gantry cranes or container cranes at intersecting tracks, enhancing operational flexibility in busy port environments.

● Mining Transportation: Supports multi-directional transport of mine car rail systems in complex terrains, ensuring efficient and reliable movement of materials in mining operations.

● Shipyard Facilities: Allows flexible movement of ships and their components during construction or repair in limited spaces or workshops, improving workflow efficiency.

● Railway Maintenance: Enables maintenance equipment to move flexibly at railway crossings, ensuring timely and effective maintenance of rail networks.

Sinchold Product Advantages

● Safety and Reliability: Rigorously tested to ensure safe operation under high-load conditions.

● Cost-Effective and Efficient: Reduces maintenance costs for rail systems and improves equipment operational efficiency.

● High Strength and Durability: Manufactured from premium alloy steel, ensuring a long service life and reduced replacement frequency.

● Customization Services: Provides non-standard sizes and special materials tailored to customer requirements.

This product is a critical component for ensuring the stable and efficient operation of crane systems in complex layouts. Selecting the right connector is essential for ensuring operator safety and enhancing equipment performance and productivity.