Tailored Crane Track Engineering Solutions by Top Manufacturer for Optimal Performance

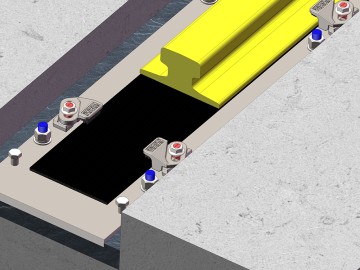

As a leading provider in Crane Track Engineering, we emphasize quality and reliability in every aspect of our work. Our products, meticulously manufactured in China, adhere to the highest industry standards. Collaborating closely with top suppliers and factories, we offer a diverse selection of crane tracks designed to enhance your operations. At SINCHOLD Co., Ltd., we focus on delivering both durable materials and innovative solutions tailored to your unique requirements. Our commitment to exceptional customer service guarantees that your inquiries are handled promptly and effectively. Partner with us to boost your productivity and operational efficiency with our premium Crane Track Engineering solutions.Methods To choose Crane Track Engineering Your Trusted OEM Partner Pioneers in the Field

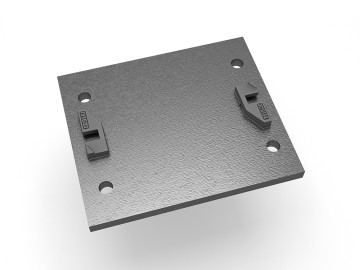

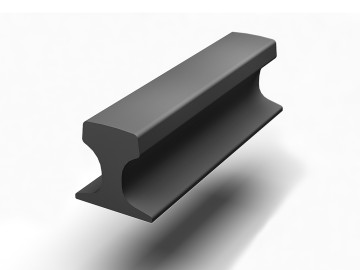

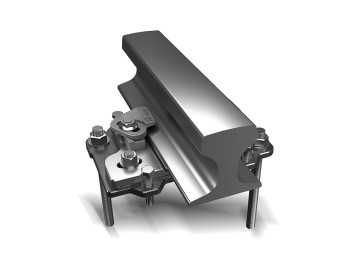

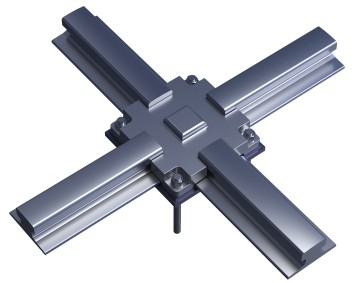

Choosing the right partner for crane track engineering is crucial for achieving efficiency and reliability in any railway project. At SINCHOLD, we proudly position ourselves as your trusted OEM partner, renowned for our expertise in the manufacturing of rail fasteners and accessories. Our commitment to engineering excellence ensures that we provide not only high-quality products, such as our railway e-clip series and turnout systems, but also unparalleled technical services, making us pioneers in the field.

What sets SINCHOLD apart is our integrated approach to every stage of the process, from production to installation. We understand the unique challenges faced by global procurement managers, and our extensive experience allows us to address your specific needs effectively. Our combined series of fastening systems is designed for durability and reliability, ensuring safety and performance under various conditions. By partnering with SINCHOLD, you gain access to innovative solutions tailored for optimal railway track performance.

As the railway industry continues to evolve, aligning with a manufacturer that emphasizes quality, reliability, and comprehensive service is essential. SINCHOLD’s dedication to excellence makes us a preferred choice for those looking to enhance their projects with top-tier rail fasteners. Trust us to be your partner in crane track engineering, and experience the difference of working with a leader in the field.

Methods To choose Crane Track Engineering Your Trusted OEM Partner Pioneers in the Field

| Criteria | Description | Best Practices | Examples |

|---|---|---|---|

| Experience | Years in the crane track engineering industry. | Choose partners with over 10 years of experience. | Established firms with a solid portfolio. |

| Technical Expertise | Skills and knowledge in engineering and design. | Look for certifications and specialized training. | Engineers with relevant certifications. |

| Quality Assurance | Standards and protocols to ensure quality. | Select companies with ISO certification. | ISO 9001 certified manufacturers. |

| Customer Support | Availability and responsiveness of support team. | Review feedback on customer service quality. | Responsive support teams with positive reviews. |

| Innovation | Adoption of new technologies and methodologies. | Evaluate companies’ investment in R&D. | Firms showcasing novel engineering solutions. |

Curated Selection of Crane Track Engineering Manufacturer Where Service Meets Innovation

C

Camila Nelson

The quality of this product is phenomenal! I truly appreciated the expertise of the customer service representatives.

29

June

2025

O

Owen Baker

The professionalism displayed by the service staff was very reassuring. A lovely experience overall.

09

June

2025

G

Grace Martinez

Very pleased with my purchase! The quality really speaks volumes about the brand.

22

May

2025

C

Charlotte Bell

Quality is unparalleled. I will definitely consider purchasing again in the future!

12

May

2025

E

Emily Clark

This product stands out for its reliability. The customer support team demonstrated great expertise and provided me with valuable insights.

09

June

2025

D

Daniel Miller

Quality is outstanding, and the team behind it is equally impressive. They addressed my concerns with utmost professionalism.

15

June

2025