When it comes to construction, the right methods can make a huge difference. "Anchoring Bolts in Concrete Foundations" is critical for ensuring structural integrity. Expert Sarah Johnson, a renowned engineer, once said, "Proper installation is key to the performance of any structure." Her insight highlights the importance of following best practices.

Achieving success with anchoring bolts requires careful planning and execution. Concrete foundations can be challenging, particularly when it comes to securing bolts effectively. A common mistake is not considering the load requirements. This step is often overlooked, but it is essential. Without the right anchors, a foundation may fail under pressure.

Moreover, weather conditions can impact installation. Cold temperatures can affect curing times. This can lead to complications down the line. Understanding these factors can prevent costly mistakes. Working with the right tools and materials is also crucial. Often, DIY enthusiasts underestimate this aspect. Mistakes happen, and reflecting on those moments helps improve future projects. Careful preparation is key to success in anchoring bolts for solid foundations.

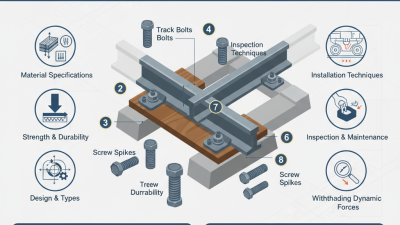

Anchoring bolts are essential for securing structures to concrete foundations. They come in various types, each designed for specific applications. Common types include expansion bolts, concrete screws, and epoxy anchors. Each type has unique strengths, making them suitable for a range of projects from residential to industrial constructions.

When selecting anchoring bolts, consider the environment and load requirements. Some bolts resist corrosion better than others. The material and finish play a crucial role in their durability. In harsh conditions, overlooking these factors may lead to premature failure. Ensure you match the bolt type to the specific load and stress it will endure.

Installation can be tricky. It's easy to misjudge the depth or alignment of the holes. Drilling mistakes can compromise the foundation's integrity. Practicing precise measurements and using quality tools helps, but mistakes can still happen. Each mishap serves as a lesson for improvement in future projects. Careful planning and awareness can lead to better outcomes.

When installing anchoring bolts in concrete, having the right tools and materials is crucial. Essential items include a hammer drill, masonry bits, a vacuum for debris, and of course, the anchoring bolts themselves. In a recent industry report, over 75% of construction failures linked to anchoring issues stemmed from improper installation and inadequate tools. This highlights the importance of preparation.

Another important aspect is selecting the correct type of anchoring bolts for your project. There are various types available, like wedge anchors and sleeve anchors. Each type serves different purposes. Understanding your project requirements can greatly impact the outcome. Use manufacturer specifications and guidelines to make informed decisions.

Do not forget about safety gear. Wearing gloves, goggles, and dust masks is essential when working with concrete. These materials can be harmful to health. Follow local regulations to ensure compliance. Preparation decreases the chance of errors. Remember, even slight miscalculations can lead to significant issues down the line. Proper planning pays off in the long run.

When installing anchoring bolts in concrete foundations, precise drilling is crucial. According to industry reports, nearly 30% of structural failures are linked to improperly installed anchors. Therefore, understanding the right drilling technique enhances safety and stability.

Start by marking the location for each bolt. Use a template for consistent spacing. To drill, select a carbide-tipped bit appropriate for the bolt size. Set your drill at a speed between 700 and 1000 RPM for optimal performance. Drilling too quickly can lead to overheating, which weakens the concrete. Monitor the depth as you go; aim for at least one-and-a-half times the anchor bolt’s diameter.

After drilling, remove dust and debris with a vacuum. This step is often overlooked, yet it is vital. Dust can prevent proper bonding of the anchor. Install the bolts while the epoxy or adhesive is still tacky. A gap of more than five minutes can compromise your anchor’s strength. While mistakes happen, careful drilling and attention to detail can significantly reduce failures. Always reflect on your process; improvement comes from understanding past oversights.

| Tip Number | Tip | Detail |

|---|---|---|

| 1 | Select Proper Anchoring Type | Choose the right type of anchor bolt based on load requirements and environmental conditions. |

| 2 | Determine Placement | Carefully plan where the anchor bolts will be placed to ensure strength and stability. |

| 3 | Use a Hammer Drill | Employ a hammer drill for effective hole drilling in concrete. |

| 4 | Mark Locations Clearly | Use a chalk line or marker to clearly denote drilling locations. |

| 5 | Choose Appropriate Drill Bit Size | Select a drill bit that matches the diameter of the anchor bolts being used. |

| 6 | Drill at a Correct Angle | Ensure holes are drilled vertically to maintain bolt strength and alignment. |

| 7 | Clean the Holes | Remove dust and debris from holes before inserting anchor bolts. |

| 8 | Use Proper Epoxy When Necessary | For added strength, use epoxy when installing anchor bolts in concrete. |

| 9 | Allow for Curing Time | Follow recommended curing time for epoxy or adhesives to achieve maximum strength. |

| 10 | Test the Installation | Conduct a load test to ensure the bolts are secured correctly and can withstand expected loads. |

Calculating load requirements is crucial for anchoring bolts in concrete foundations. Different types of bolts have varying load capacities. Understanding how to calculate these requirements helps in selecting the right anchor for your project. Consider the weight of the object to be secured, environmental factors, and possible dynamic loads. Get precise measurements to ensure safety and effectiveness.

One tip when installing anchoring bolts is to ensure the spacing is adequate. This prevents overloading a single bolt. Measure the center-to-center distance carefully. Another important aspect is to use a proper installation technique. Drilling a clean hole is vital for the bolt to fit securely. A misaligned hole can lead to failure.

When you’re unsure, it’s okay to seek help. Relying on expert advice can prevent costly mistakes. Remember, not every job is perfect. Continuous learning from experiences is vital. Measure twice, drill once is more than just a saying; it’s a principle to live by. Each installation is unique and should be treated as such. Take your time to plan and execute correctly.

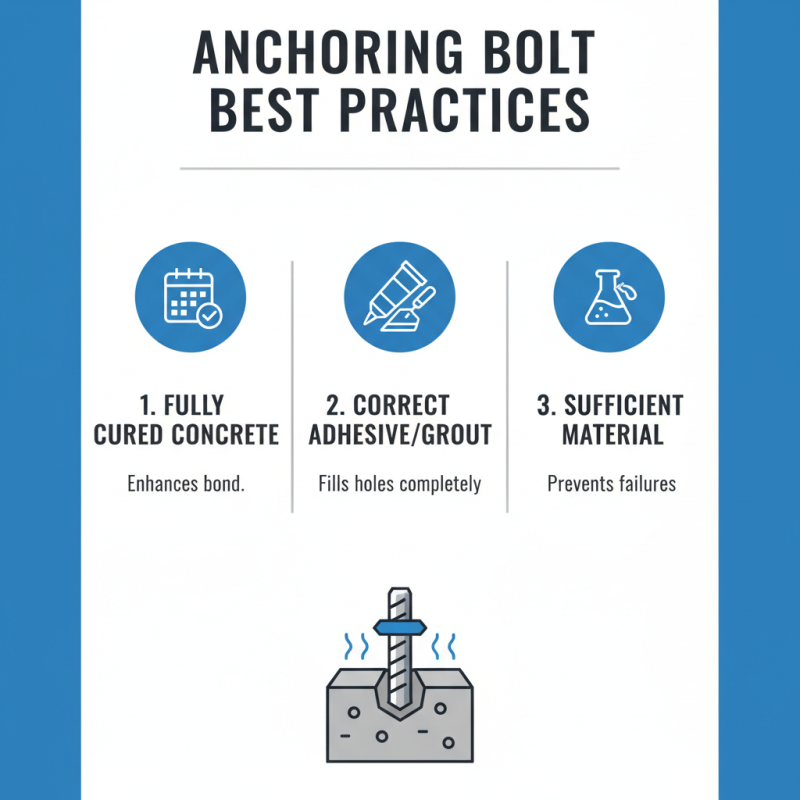

When installing anchoring bolts in concrete foundations, adhering to best practices is crucial for longevity and structural integrity. First, ensure the concrete is fully cured before drilling. This enhances the bond between the bolt and concrete. Use the right type of adhesive or grout to fill the holes. A common mistake is underestimating the amount of material needed. Insufficient adhesive can lead to failures over time.

Pay attention to the bolt placement. Respect space requirements to allow for expansion and movement. Too close together can cause stress points. Sealing the installation area is also vital. Moisture can weaken the bond. Regular inspections are recommended to catch any signs of corrosion or wear early. Not addressing these issues can compromise the entire structure.

Consider the environmental conditions as well. Changes in temperature can affect the performance of anchoring bolts. Some installations may require additional protective coatings. In harsher climates, it's prudent to reassess materials used. Learning from mistakes is essential; it helps in refining techniques for future projects.