In the world of material handling, the efficiency of gantry cranes is crucial. One of the key components enhancing this efficiency is the bolted rail clip for gantry crane runway. These clips play a significant role in securing the rails firmly. Their importance cannot be understated. The need for stability and safety is paramount in industrial operations.

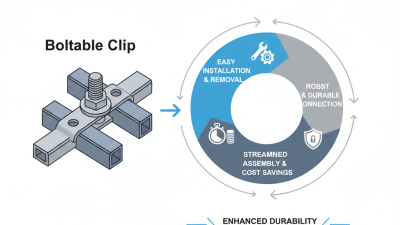

Using bolted rail clips allows for easier installation and adjustments. This adaptability can lead to reduced downtime during maintenance. Moreover, these clips provide a robust connection between the rail and the crane. It's not just about fixing the rail; it's about ensuring the entire system operates smoothly. However, one must remember that improper installation can lead to complications.

The choice of using bolted rail clips should be informed by their benefits and potential drawbacks. Reviewing the major advantages can help operators make informed decisions. Understanding the balance between securing the system and ensuring flexibility is essential for optimal performance. The bolted rail clip for gantry crane runway stands out as a reliable solution in achieving this balance.

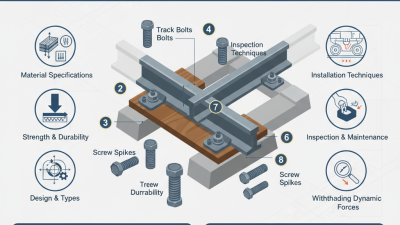

Bolted rail clips offer numerous advantages in gantry crane applications. They ensure a secure connection between the rail and the crane, enhancing stability. This is crucial since cranes operate under heavy loads and varying conditions. A sturdy clip minimizes the risk of rail misalignment, which can lead to accidents.

Another key benefit is ease of maintenance. Bolted rail clips can be quickly inspected and replaced if needed. Their design allows for straightforward adjustments, which can save time during routine checks. Effective maintenance is vital for operational efficiency. However, users might overlook the importance of regular checks. Skipping these could lead to unforeseen issues.

Furthermore, the adaptability of bolted rail clips is noteworthy. They can accommodate different rail sizes and types. This versatility makes them suitable for various gantry crane setups. Yet, adopting these clips requires careful consideration of the specific application. Not every setup might benefit equally from them. Taking the time to assess compatibility is essential.

Gantry cranes play a vital role in various industries. Their efficiency relies heavily on the stability of their rail systems. Bolted rail clips provide an excellent solution for enhancing crane performance. These clips secure the rails tightly, reducing movement that could lead to accidents. A stable rail system prevents misalignment, ensuring safer operations for workers.

Using bolted rail clips significantly improves safety. When rails are secure, the risk of derailments decreases. Workers can focus on their tasks rather than worrying about instability. A stable environment fosters productivity. However, installation must be done meticulously. Any oversight could negate the safety benefits. Periodic checks are essential. Regular maintenance ensures that the clips remain effective over time.

Incorporating bolted rail clips is not just a choice; it's a commitment to safety. The enhanced stability they offer is undeniable. Yet, it’s crucial to remember that every installation varies. One size might not fit all. Adjustments may be needed for different crane setups. Overall, while bolted rail clips improve safety, constant vigilance is required to maintain that safety.

| Benefit | Description |

|---|---|

| Enhanced Stability | Bolted rail clips provide superior grip, reducing movement and ensuring that gantry cranes remain stable during operation. |

| Increased Safety | By minimizing rail wear and tear, bolted clips enhance safety for operators and prevent accidents. |

| Cost-Effectiveness | Longer lifespan of equipment leads to reduced maintenance costs over time. |

| Ease of Installation | Bolted rail clips are designed for quick installation, minimizing downtime during setup. |

| Flexibility | Can be used with various rail sizes and configurations, allowing for versatile applications. |

| Reduced Noise | Decreases the noise produced during crane operation, creating a better work environment. |

| Improved Load Distribution | Evenly distributes loads across the rail, enhancing the structural integrity of gantry cranes. |

| Corrosion Resistance | Materials used in bolted clips are often corrosion-resistant to withstand harsh environments. |

| Enhanced Resilience | Designed to withstand high stress and dynamic forces, extending the lifespan of the rail system. |

| Compliance with Standards | Manufactured to meet or exceed industry safety standards, ensuring reliability in operations. |

When it comes to gantry cranes, bolted rail clips are a game changer. Their cost-effectiveness is one of their biggest advantages. Using these clips can reduce maintenance expenses significantly. They require less frequent replacement than traditional rail systems. This means both time and labor costs decrease.

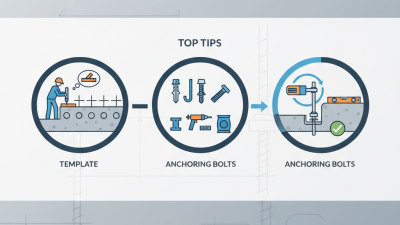

Think about this: maintenance budgets often face constraints. Choosing bolted clips can optimize these budgets. They are easy to install and replace, saving on labor costs. Regular inspections can reveal wear and tear, allowing for proactive adjustments. It’s important to keep records of these inspections for future reference.

Tips for using bolted rail clips effectively include ensuring they are properly tightened during installation. A loose clip can lead to increased wear on the rail system. Additionally, consider seasonal maintenance checks. An all-weather approach to crane care can extend the lifespan of your clips. Don’t overlook the small details; they often lead to bigger savings in the long run.

The ease of installation and replacement of bolted rail clips is a notable advantage for gantry cranes.

These clips simplify the process considerably. Technicians can attach or detach them quickly, reducing downtime during maintenance.

Time saved in installation translates to improved productivity on job sites.

This is crucial, especially in busy operations.

Moreover, bolted rail clips offer flexibility in adjustment and reconfiguration. Over time, rails may require realignment due to wear or environmental factors.

With bolted clips, this adjustment becomes straightforward. A few tools are needed, and the process can be done with minimal fuss.

Yet, there may be moments of frustration. Some technicians may face difficulties aligning the clips correctly.

This could mean extra checks are necessary before finalizing installations.

Another consideration is the need for regular inspections. Bolted rail clips, while durable, can experience wear over time.

Noticing this early requires diligence.

An inspection can seem mundane, but it saves from larger issues down the line. Everyone involved should remain vigilant about their condition.

Regular maintenance routines are essential for keeping cranes operating efficiently.

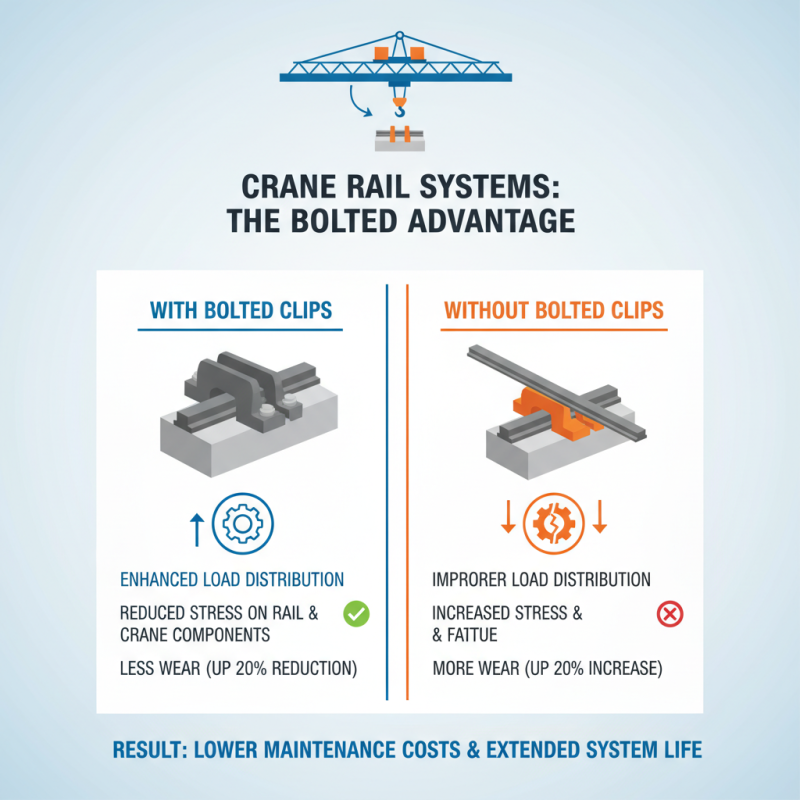

Bolted rail clips are essential in crane systems. They enhance load distribution, reducing stress on rail and crane components. Research indicates improper load distribution can lead to 20% more wear on track systems over time. This wear increases maintenance costs dramatically.

Using bolted rail clips helps evenly distribute the load. This creates stability within the crane system. According to a recent industry report, improved load distribution can reduce peak forces by 15%. With less force concentrated on specific points, rail failure becomes less likely.

However, using bolted rail clips can be a double-edged sword. Installation requires precision. Misalignment might lead to performance issues. It’s crucial to monitor the assembly closely during installation. Regular inspections are necessary to ensure ongoing effectiveness. While bolted clips improve stability, their dependence on proper installation raises questions about ongoing maintenance practices.