In the evolving landscape of construction and manufacturing, "Bolted Fixing Clips" play a crucial role. As an industry expert, John Thompson emphasizes, “Innovation in fixing clips can streamline processes and enhance safety.” This highlights the significant impact these clips have in various applications.

The trends and innovations surrounding bolted fixing clips continue to shape the industry. Companies are now focusing on materials that offer better durability and resistance to harsh conditions. One notable trend is the integration of smart technology. Sensors can now monitor stress levels, providing invaluable data to prevent failures. These innovations are not without their challenges. Cost implications and the need for worker training are areas requiring careful consideration.

While advancements abound, we must also reflect on potential pitfalls. Over-reliance on technology may lead to complacency in manual inspections. Furthermore, not all market players adapt equally. Small manufacturers might struggle to implement these innovations. Balancing tradition and innovation will be essential for future success in the bolted fixing clips sector.

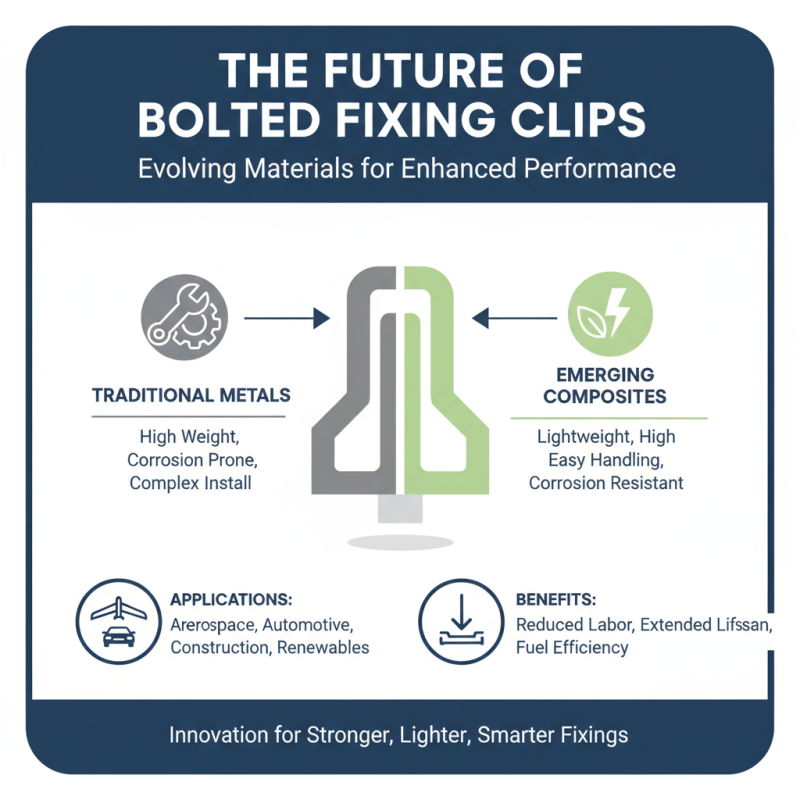

The realm of bolted fixing clips is evolving. Emerging materials are shaping their future. Lightweight composites are gaining traction. These materials offer high strength with reduced weight. This innovation allows for easier handling and installation in various applications.

Additionally, advanced technologies are transforming the manufacturing processes. 3D printing is being explored for producing customized clips. This method enhances flexibility in design. However, it also raises questions about material durability. The trade-off between customization and strength must be addressed.

Some companies are testing biodegradable materials. This shifts the focus towards sustainability. Yet, the performance of these materials in high-stress environments is still uncertain. As these trends develop, continuous evaluation is essential to balance innovation with reliability.

In 2026, the bolted fixing clip market is witnessing remarkable innovations. A recent industry report highlights a 15% annual growth in demand for advanced fixing clips. Designers are focusing on materials that enhance durability and reduce corrosion. Many new clips incorporate high-strength polymers, which can withstand extreme temperatures. This change minimizes maintenance and replacement costs in the long run.

Another key trend is the ergonomic design of clips. Many users report difficulties while handling traditional clips. The new designs aim to improve grip and ease of use. Some clips even feature flexible points that allow for better adaptability to various applications. According to a survey, 30% of professionals prefer clips that reduce hand strain. However, while these improvements are notable, challenges remain in achieving optimal cost-effectiveness.

Despite these advancements, imperfections exist. The shift to lighter materials sometimes sacrifices strength. Feedback indicates that some users still face reliability issues in certain conditions. This suggests a need for ongoing innovation. Continuous testing and user feedback will be crucial for addressing these concerns. The balance between innovation and reliability remains a key focus for the industry's future.

| Trend/Innovation | Description | Material Used | Application Area |

|---|---|---|---|

| High-Strength Alloys | Utilization of advanced materials that provide enhanced strength and durability. | Titanium and Advanced Steel Alloys | Aerospace and Heavy Machinery |

| Corrosion Resistance | Introduction of coatings that prevent rust and extend lifespan. | Zinc and Polymer Coatings | Construction and Marine Applications |

| Modular Designs | Adaptable designs that allow for quick assembly and disassembly. | Aluminum and Composite Materials | Automotive and Aerospace |

| Smart Fixing Clips | Incorporation of sensors for monitoring tension and stress levels. | High-tech Composites | Industrial and Research Applications |

| Sustainability Focus | Shift towards eco-friendly materials and production methods. | Recycled Metals and Biodegradable Plastics | General Manufacturing |

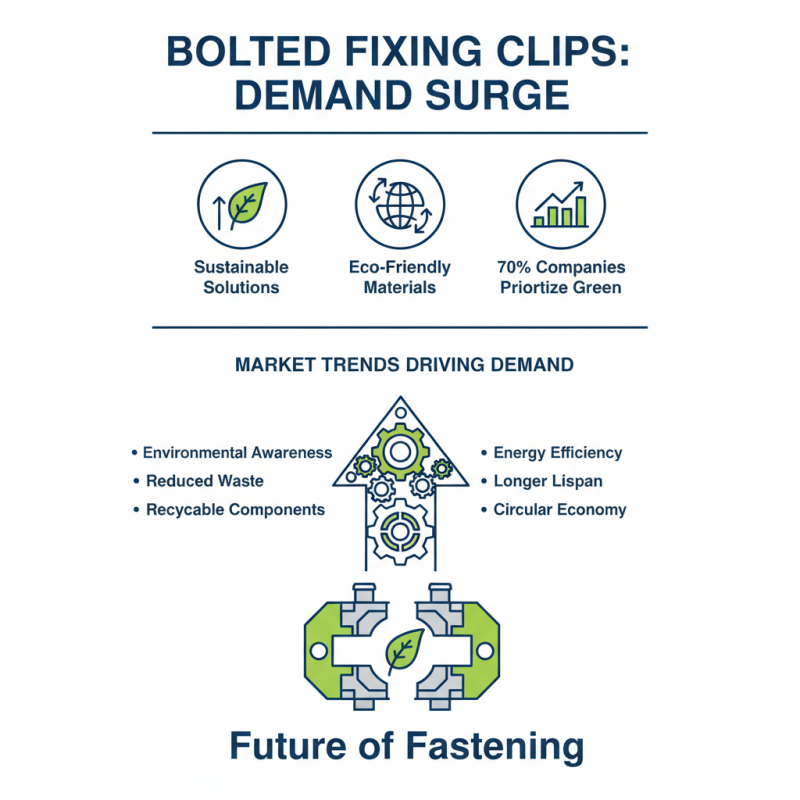

The demand for bolted fixing clips is rising due to several key market trends. Industries are moving towards sustainable solutions. This shift is driven by a growing awareness of environmental issues. Research shows that 70% of companies prioritize eco-friendly materials. This influences how bolted fixing clips are designed and manufactured.

Construction and automotive sectors are two major markets for these clips. They require durable, high-strength materials. Trends indicate an increase in demand for lightweight but robust options. Moreover, innovation is occurring in the way these clips are produced. Automation in manufacturing is enhancing reliability and efficiency. This allows for quicker production times, meeting market needs more effectively.

Tips: Always consider the strength-to-weight ratio when selecting fixing clips. A well-designed clip can greatly enhance overall product performance. Regularly inspect and test fixing clips to ensure they meet safety standards. Imperfections can lead to catastrophic failures, so attention to detail is paramount. In a fast-evolving market, staying informed on new materials and technologies is crucial for success.

In the rapidly evolving world of fixing clips, sustainability is at the forefront. The manufacturing process for these clips is increasingly focused on reducing waste. Some companies are exploring biodegradable materials. This shift helps minimize environmental impact. However, challenges remain in sourcing sustainable raw materials.

Eco-friendly practices are crucial. Many manufacturers are adopting recycled content in their clips. This practice not only reduces reliance on virgin materials but also helps lower carbon footprints. Yet, not all industries have embraced these changes. Resistance to change is still prevalent. There is a need for more education on sustainable options.

Additionally, the end-of-life impact of fixing clips needs attention. Many clips end up in landfills, contributing to pollution. Innovating solutions for reuse or recycling could address this issue. Incorporating feedback from users can guide more sustainable designs. The path forward is not without obstacles, but progress is possible.

This chart illustrates the anticipated trends in the bolted fixing clips industry for 2026, focusing on sustainability and eco-friendliness in manufacturing processes. The data reflects the percentage of manufacturers adopting sustainable practices, innovative materials, and eco-friendly designs.

The future of bolted fixing clips looks promising across various industries. As construction and manufacturing sectors evolve, the demand for innovative fastening solutions increases. Lightweight materials and enhanced durability are key focuses. These advancements could transform how assembly lines and construction sites operate.

Sustainability is also becoming a vital consideration. Eco-friendly materials in manufacturing clips could reduce environmental impact. However, challenges in balancing strength and lightness persist. Designers and engineers must cooperate closely to navigate these hurdles. There’s room for exploration and improvement in this area.

The shift towards smart technologies is noteworthy. Clips integrated with sensors could provide real-time data about structural integrity. Such innovations might improve safety and efficiency. Yet, issues such as cost and complexity remain. The industry must address these points to ensure widespread adoption.